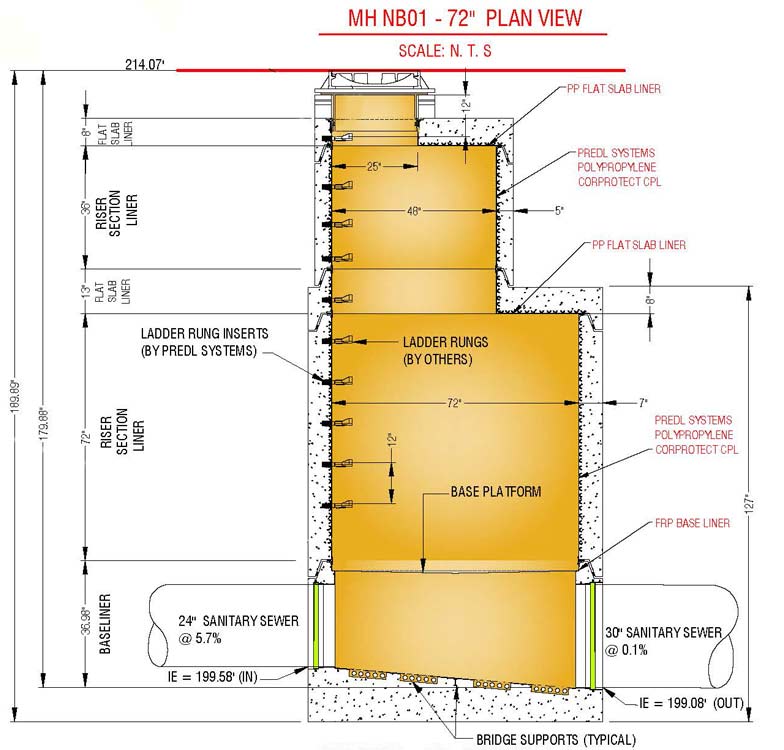

Manholes

Liners offer longer life for new DCWTS manholes

The Discovery Corridor Wastewater Transmission System project includes several new fully lined manholes and vaults where the force mains (pressurized) discharge into gravity (non-pressurized) pipes. These manholes and vaults are specifically designed to prevent the corrosion that can occur in typical concrete sanitary sewer structures.

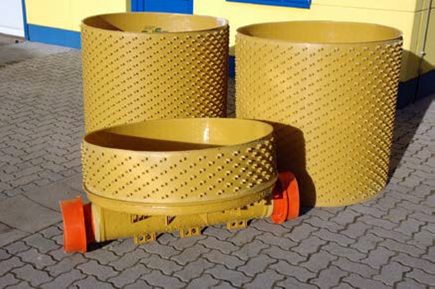

In sanitary sewers, splashing and turbulence happens where pressurized flow discharges to gravity pipes, releasing hydrogen sulfide (H2S) into the air. Where hydrogen sulfide exists in sanitary sewers, bacteria feeds on the hydrogen sulfide and excretes sulfuric acid. The sulfuric acid quickly corrodes concrete manholes and also some metals. To prevent that corrosion, each of these manholes and vaults will be lined with a molded thermoplastic reinforced polymer – Fiberglass Reinforced Plastic (FRP) and Polypropylene (PP) – cast in Vancouver, Canada by the Predl company. The liners will be imbedded in newly poured concrete at Columbia Precast Products in Washougal, Washington to provide a continuous plastic lining for the vaults and manhole base, walls and cover. The manholes and vaults will then be delivered to the project site for installation by Tapani, the project contractor. The liners are a critical component of the vapor phase odor and corrosion control approach of the project.

Benefits: The full liners will greatly increase the lifespan of the manholes and vaults, saving the District restoration and repair costs. Liners also help reduce the need for addition of chemicals, which will save about $100,000 per year in chemical costs.

Click to view photo gallery